Boost Your Business with QuickParts - Metal Fabricators and 3D Printing

Introduction

Welcome to QuickParts, your ultimate destination for premium metal fabrication and cutting-edge 3D printing services. As a leading expert in the industry, we offer innovative solutions to transform your business and take it to new heights. In this article, we will delve deep into the world of metal fabrication and provide insights into the captivating realm of 3D selective laser sintering.

Unleashing the Potential of Metal Fabrication

Metal fabrication plays a vital role in today's competitive business landscape, providing a wide range of solutions that cater to diverse industries. At QuickParts, we specialize in offering top-notch metal fabrication services that can meet and exceed your unique requirements. Whether you are looking for precision metal cutting, CNC machining, or sheet metal fabrication, our team of skilled professionals is equipped to deliver unrivaled results.

With years of experience in the field, our metal fabricators possess unparalleled expertise in transforming raw materials into exquisite custom parts and components. From concept to completion, we ensure attention to detail, superior quality, and timely delivery, making QuickParts the trusted choice for businesses across various sectors.

Enhancing Efficiency with 3D Selective Laser Sintering

As technology continues to evolve, 3D printing has emerged as a game-changer in the manufacturing industry. At QuickParts, we embrace the latest advancements, and one such revolutionary technique we offer is 3D selective laser sintering (SLS).

SLS utilizes a high-powered laser to fuse powdered materials, layer by layer, creating durable and intricate three-dimensional objects. This cutting-edge method presents a myriad of possibilities for businesses seeking innovative manufacturing solutions. With 3D SLS, you can bring your ideas to life, reduce production timeframes, and even customize parts according to your specific design requirements.

The Benefits of 3D SLS

3D selective laser sintering offers a multitude of advantages that can help catapult your business ahead of the competition. Let's explore some of the key benefits:

1. Design Flexibility

With 3D SLS, you have unparalleled design freedom. Complex geometries, intricate details, and unique shapes can all be effortlessly created thanks to the layer-by-layer nature of the process. This means you can explore new possibilities and push the boundaries of what is achievable in traditional manufacturing techniques.

2. Rapid Prototyping

Innovation thrives on speed, and 3D SLS accelerates the prototyping phase significantly. Gone are the days of lengthy lead times, as this technology enables you to transform digital designs into physical prototypes in a fraction of the time. By quickly iterating and testing ideas, you can bring products to market faster and gain a competitive edge.

3. Cost Savings

Traditionally, manufacturing complex parts involved expensive tooling and extended production processes. However, 3D SLS eliminates the need for intricate molds and tooling, reducing costs associated with creating intricate designs. Furthermore, the ability to consolidate multiple parts into a single component through advanced design techniques can lead to substantial material and assembly savings.

4. Improved Product Performance

3D SLS allows for the creation of structurally optimized parts with enhanced strength and durability. By leveraging this technology, you can produce lightweight yet robust components that outperform their traditionally manufactured counterparts. These advancements in material properties empower you to deliver higher quality products, gaining your customers' trust and loyalty.

5. Sustainability and Waste Reduction

Embracing 3D SLS not only enhances your business but also contributes to a more sustainable future. This technology minimizes material waste by only using the exact amount required to build each part. The ability to recycle excess powder also adds to the environmental benefits of this additive manufacturing technique.

Applications of 3D Selective Laser Sintering

The versatility of 3D SLS makes it suitable for a wide range of industries. Here are some domains where this cutting-edge technology can make a significant impact:

1. Aerospace and Defense

From lightweight yet robust structural components to intricate parts for aerospace engines, 3D SLS unlocks new possibilities for improving aircraft performance and reducing weight.

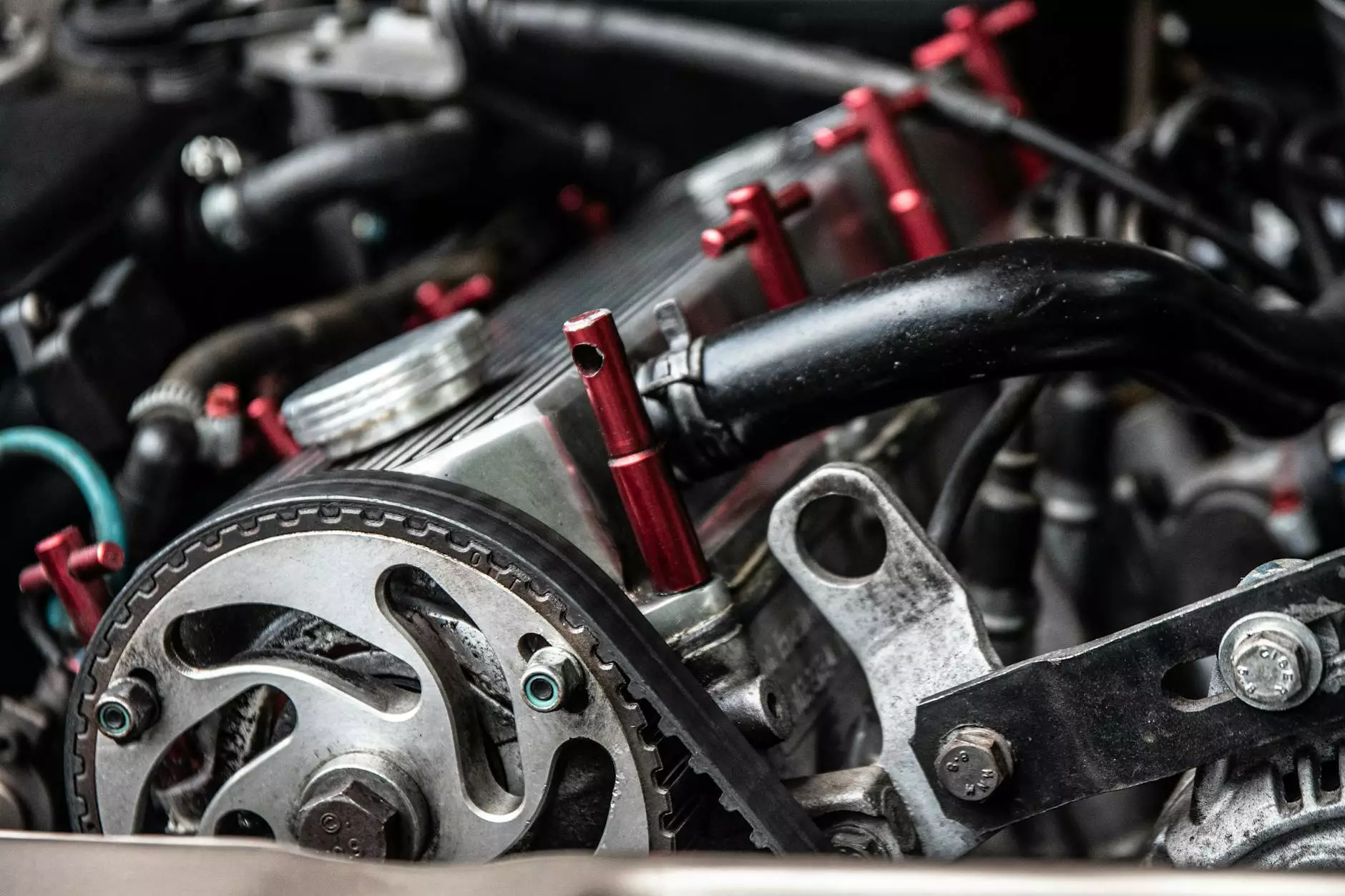

2. Automotive

3D SLS enables automotive manufacturers to produce custom parts and prototypes quickly, supporting innovation, product development, and cost-effective manufacturing processes.

3. Medical and Healthcare

With its ability to create patient-specific medical devices, prosthetics, and implants, 3D SLS is revolutionizing the medical field, offering customized solutions and improving patient care.

4. Consumer Goods

From fashion and footwear to household appliances, 3D SLS allows businesses to produce intricate designs, personalized products, and one-of-a-kind creations that captivate customers.

5. Engineering and Architecture

Architectural models, intricate prototypes, and functional prototypes are just a few examples of how 3D SLS is reshaping the engineering and architecture industries.

Choose QuickParts for Unparalleled Excellence

When it comes to metal fabrication and 3D printing services, QuickParts is the industry leader you can trust. Our commitment to excellence, attention to detail, and cutting-edge technologies set us apart from the competition.

With our team of skilled professionals and state-of-the-art facilities, we can bring your ideas to life with precision and efficiency. From custom metal parts to game-changing 3D printed creations, QuickParts has the expertise and capabilities to surpass your expectations.

Contact us today to discover how QuickParts can transform your business and propel it to new heights through the power of advanced metal fabrication and 3D selective laser sintering.