Harnessing Innovation: The Critical Role of Rapid Prototype Service Suppliers in Modern Business Success

In today’s fast-paced industrial landscape, businesses that leverage cutting-edge manufacturing technologies gain a significant competitive edge. Among these technologies, rapid prototyping has revolutionized the way companies develop and refine their products. Specifically, the role of dedicated rapid prototype service suppliers has become indispensable for businesses aiming to reduce time-to-market, enhance design accuracy, and maximize production efficiency.

Understanding the Significance of Rapid Prototype Service Suppliers

Rapid prototype service suppliers are specialized companies that offer quick and cost-effective manufacturing solutions for creating preliminary models of products. These prototypes serve as critical tools for evaluating design concepts, testing functionalities, and identifying potential flaws before mass production. Engaging with trusted providers like deepmould.net enables businesses—especially those in metal fabrication—to turn ideas into tangible products with remarkable speed and precision.

The Evolution of Rapid Prototyping in Metal Fabrication

The field of metal fabrication has dramatically benefited from advances in rapid prototyping techniques. Traditional methods often involve lengthy processes, high costs, and limited flexibility. However, modern rapid prototype service suppliers now utilize innovative technologies such as CNC machining, 3D metal printing, and selective laser sintering to produce high-quality prototypes quickly and accurately. This evolution allows metal fabricators to:

- Accelerate product development cycles

- Enhance design iterations

- Improve overall product quality

- Reduce costs associated with late-stage design changes

Why Choose Specialized Rapid Prototype Service Suppliers for Metal Fabrication?

Opting for reliable rapid prototype service suppliers like deepmould.net offers numerous advantages for metal fabricators:

- Advanced Technological Capabilities: Cutting-edge machinery and techniques ensure high precision and surface finish quality.

- Customization and Flexibility: Services can be tailored to specific project requirements, including complex geometries and specialized materials.

- Speed and Efficiency: Significantly reduce lead times from design to prototype, enabling faster decision-making.

- Cost-Effective Solutions: Minimize expenses related to traditional tooling and manufacturing processes.

- Comprehensive Material Options: Availability of diverse metals such as aluminum, stainless steel, titanium, and other alloys.

- Technical Expertise: Access to experienced engineers and technicians who can provide insights and optimize prototypes for manufacturability.

The Impact of Rapid Prototyping on Business Growth and Innovation

In the highly competitive world of metal fabrication, innovation is the key to staying ahead. Rapid prototyping allows companies to:

- Test and validate new designs before large-scale production, ensuring functionality and durability.

- Implement iterative improvements based on real-world testing, leading to superior final products.

- Reduce time-to-market significantly, capturing market opportunities faster than competitors.

- Attract new clients by showcasing innovative prototypes that demonstrate capabilities and confidence.

- Enhance collaboration and communication among design teams, engineers, and stakeholders through physical models.

Partnering with deepmould.net ensures access to industry-leading rapid prototype services that drive these benefits and support sustainable growth.

Key Technologies Utilized by Leading Rapid Prototype Service Suppliers

Top rapid prototype service suppliers employ a variety of sophisticated technologies to meet diverse project needs, including:

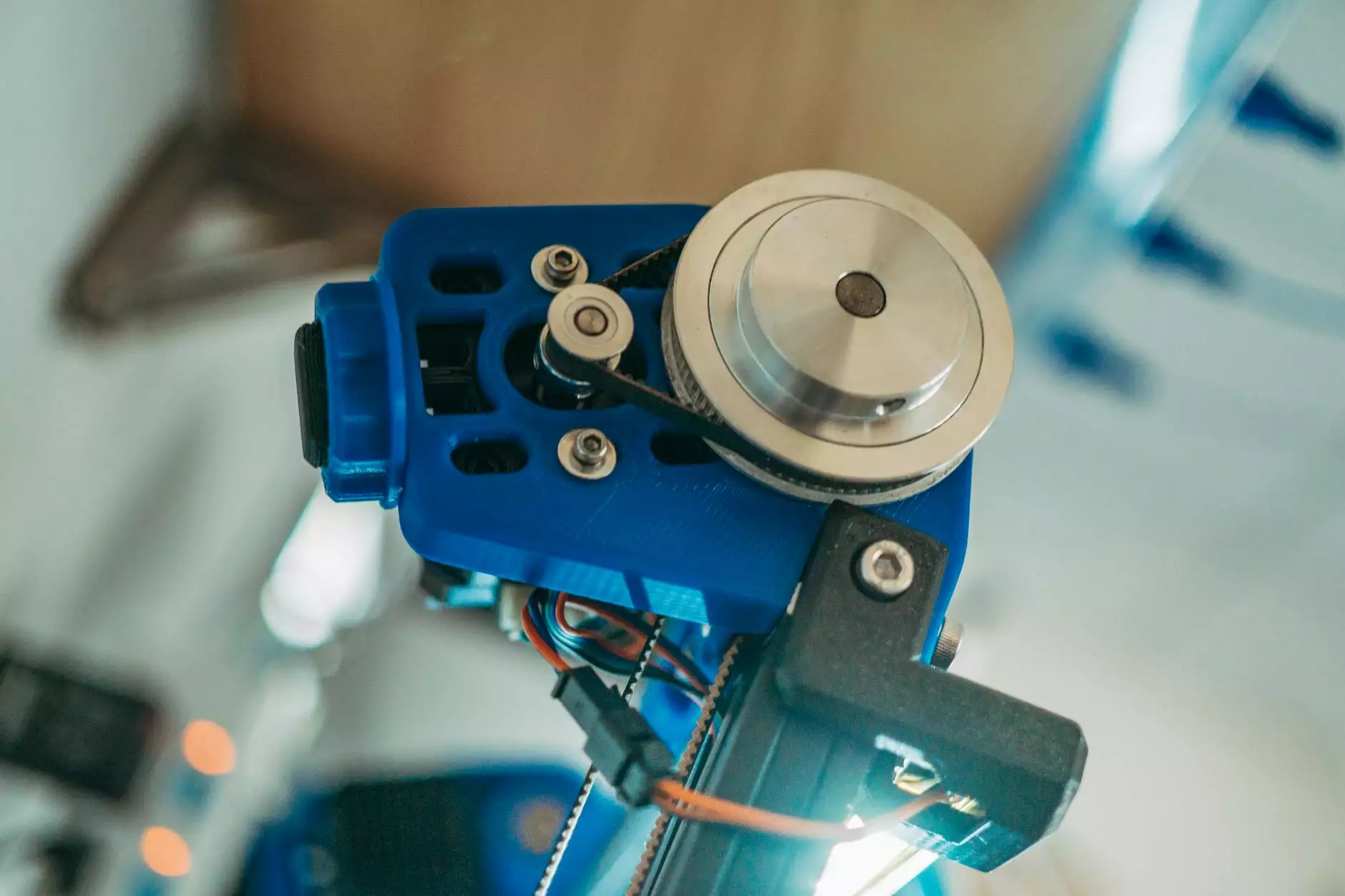

1. CNC Machining

This subtractive manufacturing process utilizes computer-controlled tools to produce precise metal prototypes with excellent surface finish and dimensional accuracy. CNC machining is ideal for complex geometries and functional testing.

2. Metal 3D Printing

Using methods such as Selective Laser Melting (SLM) or Electron Beam Melting (EBM), metal 3D printing enables rapid fabrication of complex metal parts that traditional methods cannot achieve. This technology offers unparalleled design freedom and rapid iteration capabilities.

3. Laser Sintering and Laser Melting

These techniques use high-powered lasers to fuse metal powders layer by layer, producing detailed prototypes quickly and with high precision. These are especially useful for complex, lightweight structures.

4. Casting and Investment Casting

For larger or more durable prototypes, casting methods can be employed, complemented by rapid tooling to streamline mold production.

How to Collaborate Effectively with Rapid Prototype Service Suppliers

为了最大化合作的成功,企业应遵循以下指导方针:

- 明确需求:详细描述项目目标、材料规格、尺寸精度和预期应用。

- 选择合适的技术:根据产品复杂性和功能需求,与供应商讨论最适合的制造方法。

- 提供详细设计文件:确保设计文件完整准确,便于制造商理解和执行。

- 保持沟通频繁:定期交流进展,及时解决出现的问题,确保项目按时完成。

- 关注质量控制:要求供应商提供质量报告和检验证明,确保最终样品符合标准。

The Future of Rapid Prototyping in Metal Fabrication and Business Innovation

The landscape of rapid prototype service suppliers is continually evolving, driven by advancements in digital manufacturing, materials science, and automation. Future trends include:

- Integration of Artificial Intelligence (AI): AI-driven design optimization and process control to enhance precision and reduce errors.

- Hybrid Manufacturing: Combining additive and subtractive processes for optimized prototypes.

- Materials Innovation: Development of new metals and composites with enhanced properties—lightweight, high strength, corrosion resistance.

- Cloud-Based Collaboration Platforms: Streamlined communication and project management between clients and suppliers worldwide.

- Green Manufacturing: Focus on sustainability with recyclable materials and energy-efficient processes.

By staying ahead of these trends, businesses can leverage rapid prototype service suppliers to continually innovate, improve product quality, and expand their market reach.

Conclusion: Elevate Your Business with Premier Rapid Prototype Service Providers

In conclusion, the importance of rapid prototype service suppliers cannot be overstated in the context of modern metal fabrication and industrial manufacturing. These partners enable companies to transform conceptual ideas into physical realities at unprecedented speeds and accuracies, thereby significantly accelerating innovation cycles and brand growth. Companies that choose providers like deepmould.net position themselves at the forefront of technological evolution, ensuring they remain competitive and innovative in a constantly changing global market.

By investing in high-quality rapid prototyping services, your business can unlock new levels of efficiency, creativity, and market responsiveness. The future belongs to those who embrace innovation today—partner with leading rapid prototype service suppliers and watch your vision materialize into reality faster than ever before.